|

As is generally known, one of the main laws of engineering systems (ES) evolution is the law of increasing the engineering system ideality. In accordance with that law, ES evolves towards the increase of ideality. The limit in increasing the degree of ES ideality is such a state at which ES completely disappears, while its function is performed.

The practical method for providing the ES ideality is trimming. In accordance with that method, trimming conditions are formulated for the ES components: the functions of the components are transferred to other components and to the supersystem's elements (if those elements have enough resources).

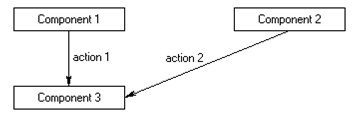

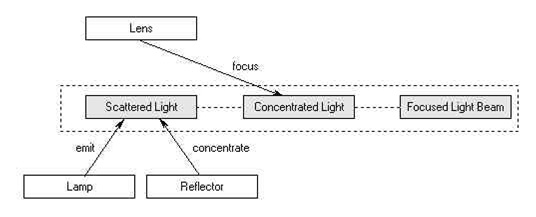

As a result, a problem is formulated aimed at the performance by the supersystem's components and elements of the vanished component's functions [1]. Normally, selected for trimming is a component with a very low ratio of the number and quality of functions to negative factors (for instance, to cost, the number and complexity of problems, etc). Let us consider a standard trimming situation (Fig. 1).

Fig. 1. Standard functional scheme

Component 1 and Component 2 act on Component 3.

Suppose we are trimming Component 1 (which, for instance, causes multiple problems and is very expensive).

Standard trimming rules.

Component 1 may be removed from the system if:

- Function [action1] [Component 3] is performed by another object (for instance, by Component 2, a supersystem's object or even by a new component);

- It is not necessary to perform the function [action1] [Component 3];

- Component 3 is also trimmed (the same trimming rules are applied to it).

Each trimming rule determines a new problem. If this problem is solved, then such an engineering system becomes simpler and less expensive. In addition, problems related to the trimmed component also disappear.

The value of component trimming problems consists in that they are generally unexpected for a designer (ES designers normally do not see them) and allow finding new effective ways of ES perfection.

There are also similar rules for production processes, when functions of one production operation are transferred to another operation.

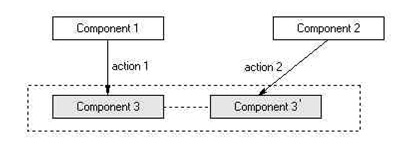

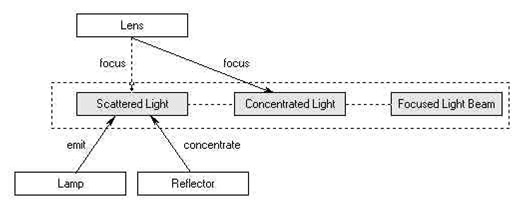

The analysis of engineering system functioning proved that many engineering systems have elements (product, component or element of supersystem) which change as the system works. This means that such elements turn to their own modifications (Fig. 2). In this case, it becomes possible to consider the production process performed within the framework of the engineering system.

Fig. 2. Functional scheme with modified element

Component 3 is transformed to its modification - Component 3' by the action 1. Component 3' is acted upon by Component 2. There are actually two production operations:

- Component 1 treats Component 3 by the "action 1".

- The "tool" - Component 2 - treats Component 3' by the "action 2".

For such situations, in addition to "standard" rules of trimming of ES components, it is also possible to use rules for trimming production process operations in the course of idealization [2].

One of the possible sets of trimming rules for the given situation for Component 1

Component 1 may be removed if:

- The function [action1] [Component 3] is performed by another object (for instance, by Component 2, a super-system object or even by a new component);

- It is unnecessary to perform the function [action1] [Component 3'];

- The action [action1] is performed by another component (for instance, by Component 2) and is directed at the modification [Component 3] (for instance, at Component 3').

- [Component 3] is absent.

The last rule means that the function is performed during another operation.

In a general case, the set of trimming rules can vary depending on the logical link between the considered operations.

The use of a wider set of rules allows detecting new problems, the solution of which may cause a considerable improvement to the engineering system functioning.

Of interest is the case when one of the element's modifications is trimmed.

Suppose we are trimming Component 3.

If it does not perform any useful function, the trimming rule will concern only the "ingoing" connections:

Component 3 may be removed if:

- It is unnecessary to perform the action ;

- The action is directed at another modification of Component 3 (for instance, at Component 3').

Such trimming rules also lead to the formulation of problems the solution of which very often cause a radical change in the system's functioning up to a change of the principle of its action.

Let us consider an example.

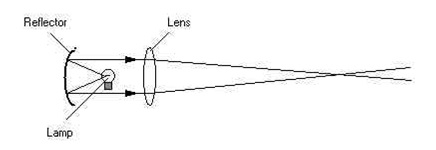

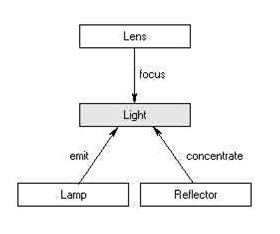

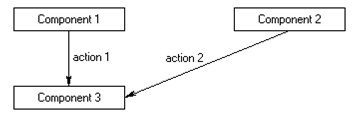

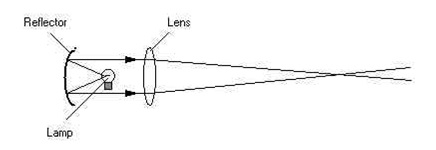

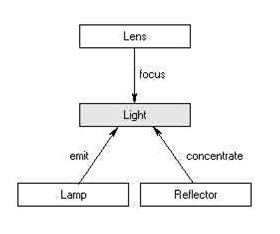

Fig 3. presents a fragment of a flash-light scheme, and Fig.4 shows a fragment of the functional scheme. The lamp emits light. The reflector concentrates the light and forms a light beam. The lenses focus the light. In Fig. 3 all the three actions are directed at one object - light.

Fig. 3. The reflecting part of a flash-light

Fig. 4. A fragment of a standard functional scheme of a flash-light

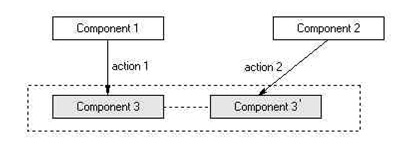

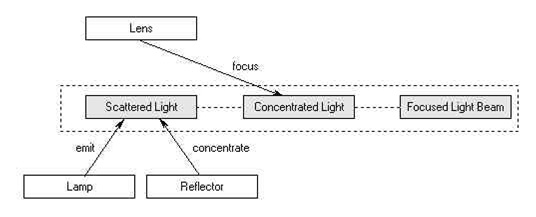

By analyzing this scheme, one can see that the system has several sequentially produced light modifications. We can speak here about three modifications of light. The lamp emits not just light, but scattered light. The reflector, due to its shape, concentrates this light, that is, transforms it to "concentrated" light. And the lens acts on the concentrated light to focus it and to change it to "focused light".

A respective functional scheme is shown in Fig. 5.

Fig. 5. A fragment of a standard functional scheme of a flash-light with modified "Light"

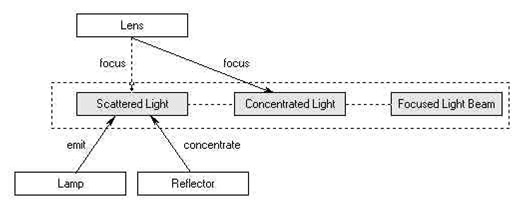

Strictly speaking not only concentrated light from the reflector gets into the lens, but also the flight from the lamp. That is why the lens tries to focus that light as well, but does not do it properly. The final version of the model is shown in Fig. 6.

Fig. 6. The specified functional scheme of a flash-light with modified "Light"

Let us apply the trimming rules to the object Reflector shown in Fig. 4.

The reflector may be removed if:

- The function [concentrate] [Light] is performed by the object Lamp or Lens;

- It is unnecessary to perform the function [concentrate] [Light];

- Light is also trimmed (the same trimming rules are applied to it).

Two problems derive from the rules 1 and 2. Rule 3 is not applicable at all, because Light is not allowed to be trimmed because of the loss of functionality.

If we consider the trimming of the same reflector on the scheme with light modifications (Fig. 6), we'll obtain the following set of trimming rules.

The reflector may be removed if:

- The function [concentrate] [Scattered Light] is performed by the object Lamp or Lens;

- It is unnecessary to perform the function [concentrate] [Scattered Light];

- The action [concentrate] is performed by the component (Lens) on [Scattered Light];

- [Scattered Light] is absent.

Each of the trimming rules generates interesting problems, the solving of which can cause a considerable improvement of the design. Rule 3 leads to a promising problem of a very interesting and serious change of the system.

Rule 4 actually requires trimming of the object Scattered Light, which is now possible because trimmed is not the entire Light, but only one of its modifications.

Scattered Light may be removed if (the trimming rules should be applied for two ingoing actions):

- It is unnecessary to perform the action [concentrate];

- It is unncecessary to fulfil the action [emit];

- The action [concentrate] is directed at another modification of Concentrated Light;

- The action [emit] is directed at another modification of Concentrated Light.

The action of rule 4 leads to the problem of how to make Lamp emit Concentrated Light. Solving this problem may lead to a system with a new principle of action having better performance than the initial ES.

Thus, considering the production processes in the context of the rules of engineering systems allows creating a full set of trimming rules (and problems that derive from them) that open new trends in the improvement of engineering systems.

References:

- Osnovnye polozheniya metodiki provedeniya funkcional'no-stoimostnogo analiza: Metodicheskie rekomendacii. - M, InformFSA, 1991.

- Gerasimov V. M., Litvin. Uchet zakonomernostej razvitiya texniki pri provedenii funkcional'no-stoimostnogo analiza texnologicheskix processov. V sbornike: "Praktika provedeniya funkcional'no-stoimostnogo analiza v e'lektrotexnicheskoj promyshlennosti" -M.: E'nergoatomizdat, 1987, pp. 193-210.

|

вверх

вверх