Abstract

First of all, I want to introduce LS Cable briefly. LG-Cable

changes the name of company to LS-Cable because the ownership

of company is changed in 2005. LS Cable produces not only

cables but also various products like heat pipe, refrigerator,

injection machine, etc. Since 2001, LS Cable has tried to enhance

R&D processes and manufacturing processes by applying TRIZ.

Therefore, LS Cable opened TRIZ education course and have

taught full process of TRIZ to research engineers. And TRIZ has

been adapted to practical engineering projects.

Several successful results were achieved through co-work with

TRIZ team and research engineers. For instance, the quality of

Polymer Insulator and Heat Shrinkable Tube were improved

dramatically. The tolerance of Heat Shrinkable Tube was

relatively more than 10mm and the production speed was limited

by the tolerance. Some solutions which satisfy production speed

and quality were developed by TRIZ. And the tensile strength of

Polymer Insulator was increased by TRIZ, too.

In this paper, TRIZ applications and activities in LS Cable will

be discussed with example of Heat Shrinkable Tube and full

processes.

1. Introduction

LS-Cable, which was one of LG group, was founded in 1962.

Originally it was a company which produce and sell cable or wire,

but today LS-Cable produce lots of product not only cable, but also

tractor, air-conditioning system, small heat pipe in machinery

division, and Li-ion battery, polymer switch in component division.

Business environment of 21 centuries is always changing rapidly,

and the company which evolutes fast can only survive in these

severe competitions.

What is the key point to survive in the worldwide competitions?

In the past, the company which makes the same product at the lower

cost can be successful. Nowadays the company which makes new

paradigm can hold a dominant position.

To make new paradigm, lots of companies put their money to

enhance and to improve R&D process more effectively.

LS-cable noticed that TRIZ can help the research engineers solve

engineering problems and generate new concepts. LS-cable noticed

that there are some differences between TRIZ and other design or

optimization methods. TRIZ is not the methods for quality

management or optimization. It is a method for changing existing

system to other system. TRIZ is very strong methods for generating

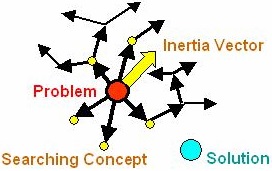

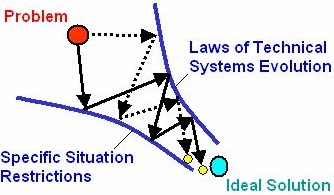

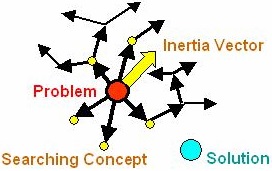

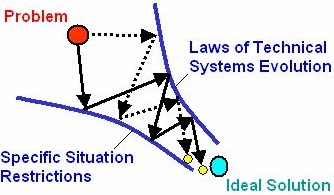

new concept and system. Figure 1 is the conventional process to

develop solution in the past, and Figure 2 is TRIZ method for

guiding right solution of engineering problems.

Figure 1. Methods are based on Trial and Error approach

Figure 2. TRIZ directs a problem to Ideal Solution

2. TRIZ History and Process in LS-Cable

In 2001, LS-Cable introduced TRIZ to the research engineers and

in 2002 two TRIZ experts are invited from LG-electronics, and they

carried out 3 projects.

During co-work with them, they suggested several good concepts

which can solve the engineering problem.

In 2003, LS-cable decided to invite a Russian TRIZ expert to

spread TRIZ and adapt to the research engineers. Since 2003, 12

research engineers have graduated 96 hours TRIZ course with their

project to be a TRIZ solver, and 16 projects were done by using

TRIZ. And about 17 patents are made through this co-work with

TRIZ team.

From 2003 to 2004, LS-Cable’s TRIZ activities have been

focused on supporting individual projects. TRIZ team carried out 13

projects and has made 20 patents. In LS-Cable, the TRIZ projects

are usually selected by both engineers and project leaders. Some of

engineers visit TRIZ team to discuss their engineering problem, if

the problem needs kind of computational analysis or optimization

(not suitable to TRIZ), TRIZ team pass the problem to

computational simulation team.

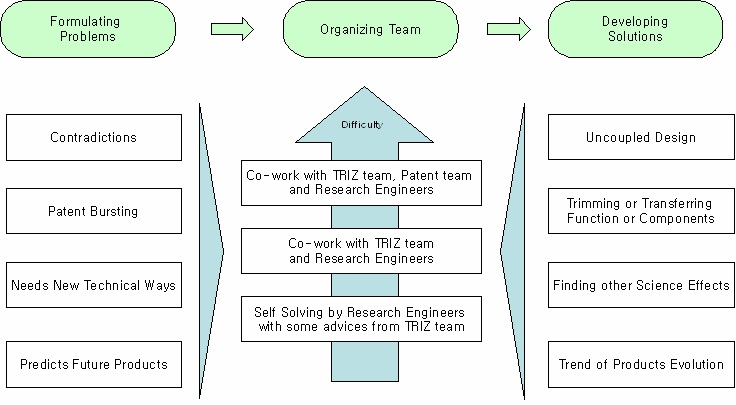

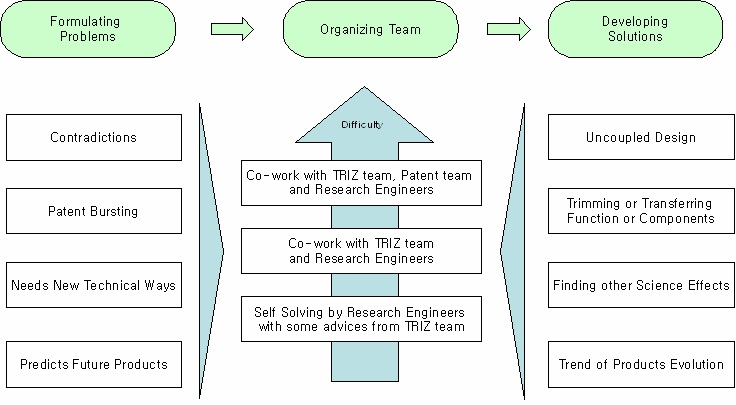

Anyway, there are usually 4 types of engineering problems.

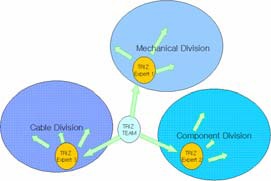

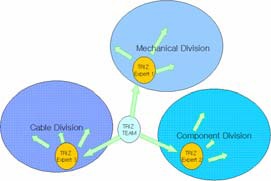

Figure 3. TRIZ process of LS-Cable

In Figure 3, the TRIZ process of LS-Cable is shown. After

formulating engineering problem by discussion with research

engineer, the level of problem difficulty is set. If the problem needs

some of information search, TRIZ team suggested that the research

engineer uses TRIZ software and patent analyzing system. In case

of the problem which has strong contradiction, TRIZ team and

researchers start to co-work for solving problems. In the case of

avoiding patents, TRIZ team, researchers, and patent team help each

other and share information to develop new methods.

But there are several problems only to support engineering projects.

There are saying “Give a man a fish and you feed him for one day.

Teach the people to fish and you feed them for all time”

Only giving idea cannot help them to use TRIZ continuously.

After finishing co-work, they didn’t use TRIZ because TRIZ team

only gave them ideas.

In 2005, LS-Cable decided to build infrastructure in the research

center to spread TRIZ. And TRIZ S/W introduction course was done

to all research engineers.

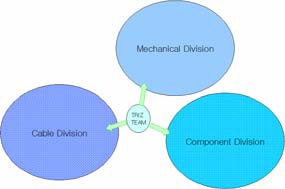

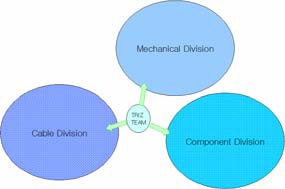

To spread TRIZ and build infrastructure, LS-TRIZ team noticed

that training several TRIZ experts in the company can be effective

way to spread TRIZ as shown in Figure 4.

|

~2004

|

~2005

|

Figure 4. 2005 plan for building Infrastructure in LS-Cable

During S/W education, survey about TRIZ was investigated and

LS-TRIZ team came to know their needs. After that, TRIZ-team

classified every project in the company according to the level and

type of engineering problem of each projects. In 2005, LS-Cable

will establish infrastructure of TRIZ and support the engineers who

want to be TRIZ-experts.

3. Case Study; Introduction of Heat Shrinkable Tube

Since 2001, some of projects show that it is possible to make

successful result by applying TRIZ. The project of improving the

quality of Heat Shrinkable Tube is one of the successful examples.

Heat Shrinkable Tube is a rubber tube which is usually used for

insulating wire connection area. Because it memorizes its original

diameter, it shrinks in a second when thermal energy is applied as

shown Figure 5.

Figure 5. Heat Shrinkable Tube

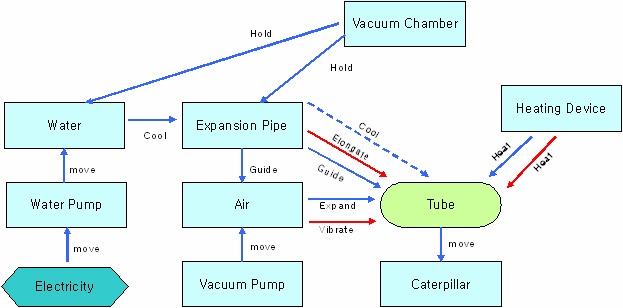

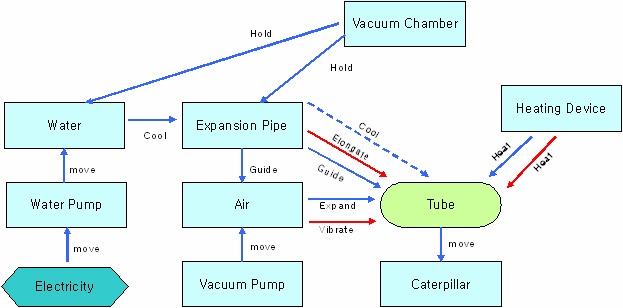

First of all, we have to analyze engineering system to find

technical problem. Usually functional analysis is used for finding

problems.

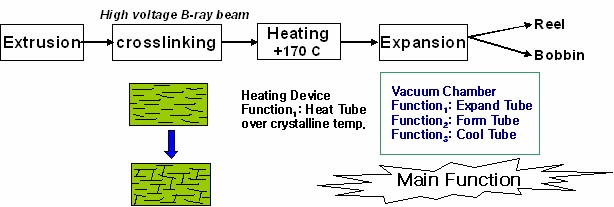

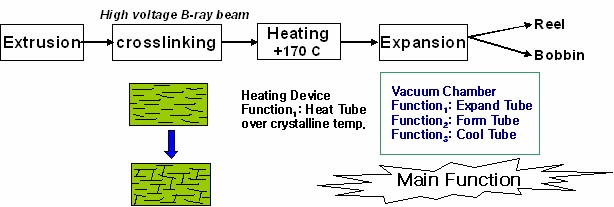

Figure 6. Process of Heat Shrinkable Tube manufacturing

The process which makes Heat Shrinkable Tube is shown in

Figure 6. At first, the original tube is heated over 170’C and is

introduced into the expansion pipe which make tube expanded.

After Expanding, the tube is cooled rapidly because the surface of

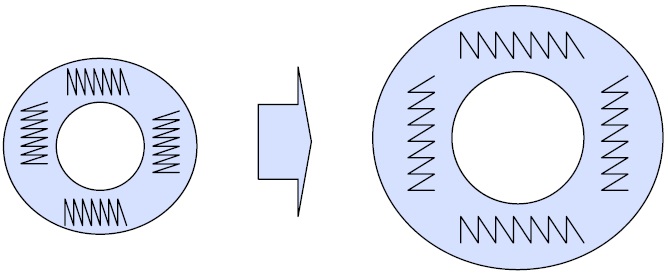

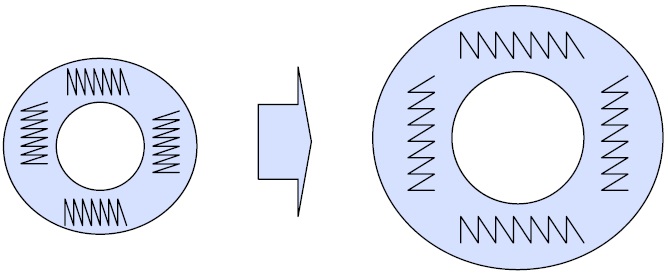

tube contacts to the wall of expansion pipe as shown in Figure 7.

During the process, shape memory effect is generated in the tube

like figure 8. It is easy to think that there are some springs inside

Heat Shrinkable Tube.

Figure 7. The Process of Expanding Heat Shrinkable Tube

Figure 8. Springs inside of Heat Shrinkable Tube elongated

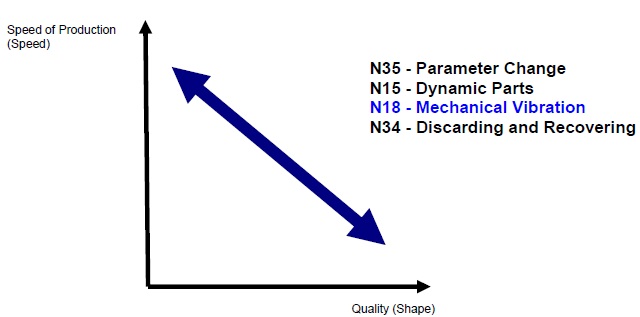

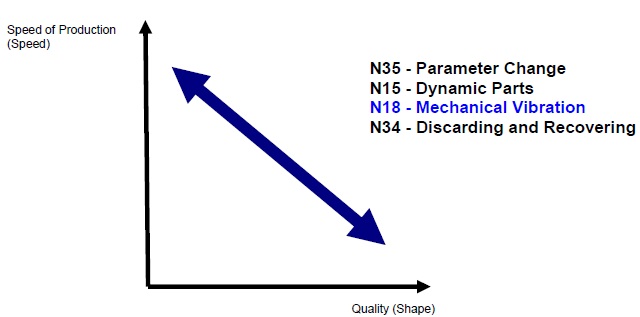

At that time, the engineers want to increase the speed of

producing Heat Shrinkable Tube. But when the speed of process is

increasing, the longitudinal elongations of Heat Shrinkable Tube

become more irregular after shrinking.

Even though the Heat Shrinkable Tube is cut into the same length,

after shrinking the length of each part becomes different because the

elongation during expansion process is different. In this case it can’t

insulate the electronic component. Figure 9 shows the problem of

heat shrinkable tube.

Figure 9. Irregular Longitudinal Extension of Heat Shrinkable Tube

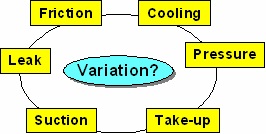

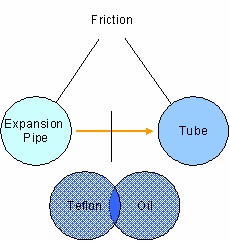

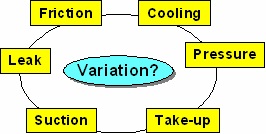

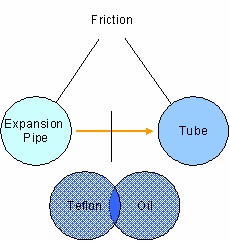

During rapid expansion inside the expansion pipe, friction is

generated between tube and the wall of expansion pipe. Also

vacuum is applied inside of expansion pipe. The pressure is not

stable. Cooling is also important to decrease time for longitudinal

elongations. Figure 10 shows several estimated reason of problem.

Figure 10. Estimated Source of Problem

Customers of LS-Cable wanted to buy Heat shrinkable Tube

which has more regular elongation change. The researchers tried to

improve the problem by changing only some of parameters, for

example, using colder water to enhance cooling of expansion pipe,

trying to stabilize vacuum pressure, Teflon coating inside of

expansion pipe or putting oil to reduce friction (Figure 11). But they

were not so effective and generate several undesirable effects.

Figure 11.Past Trial to Solve Problem

TRIZ team started to co-work to improve the quality of Heat

Shrinkable Tube. At first, TRIZ team formulates the initial situation

and problem modeling as shown in Figure 12.

Figure 12.Brief Function Modeling of Expansion Pipe

4. Case Study: Developing New Concepts for Shrinkable Tube

During formulating Problems, some contradictions are derived

from analysis. Using this problem modeling, more than 10 concepts

were generated to solve the tube’s irregular elongation problem.

At first, TRIZ team found technical contradiction between

expansion pipe and Heat Shrinkable Tube. If the speed of

production gets faster and faster, the longitudinal elongation became

bigger. Figure 13 shows technical contradiction and recommended

inventive principles.

Figure 13. Technical Contradiction of the system

To reduce friction between expansion pipe and Heat Shrinkable

Tube, mechanical vibration for reducing friction is suggested, but it

needs more cost and device. It increases complexity of technical

system, so this method couldn’t be used.

TRIZ team focused on one of the contradictions and it was also a

psychological inertia. The contradiction was that the tube should be

hot and cold, which is physical contradiction.

If the tube is cold, no elongation is occurred in the Heat

Shrinkable tube, but the tube can not be expanded. Engineers

thought that the tube must not be cold to make expansion process.

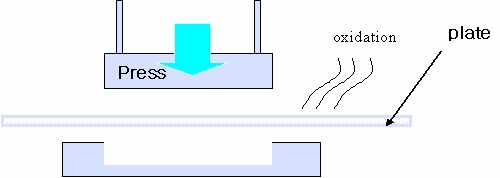

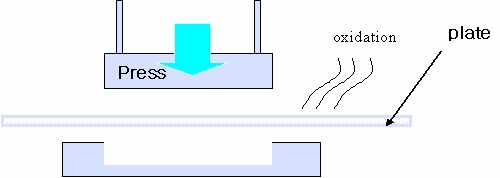

TRIZ team found a similar problem and solution in the other

area’s examples. It was a pressing and bending process for plate.

In Figure 14, It needs over 1200oC temperature to bend the plate

by press, but over 800oC the plate is oxidized. This problem needs

high and low temperature at the same time.

To solve the contradiction, the engineers of the press area used

surface cooling method. The plate can be bended because the plate

is over 1200oC on the whole, and it is not oxidized because the area

which meets air is below 800oC.

Figure 14. Prevent oxidization during pressing

TRIZ team decided to import the method into expansion pipe

system. First of all, the operating time and operating zone were

checked. Operating time means the duration time of tube in the

expansion pipe.

- operating zone : surface of tube

- operating time : 0.01sec

TRIZ team and research engineers decided that the method of

pressing plate without oxidation can be used to reduce the irregular

elongation of Heat Shrinkable Tube.

To make similar effect, new design of expansion pipe is

suggested in Figure 15.

Like pressing process, if only surface of tube is cooled, the skin

is hardened and it can resist the friction between the wall and tube

as shown in Figure 16. It makes little elongation of tube during

expansion. On the whole, because the tube is hot, the tube can be

expanded easily.

To make surface hard, peltier cooler is applied in the upper area

of the expansion pipe, because air or metal pipe surface with water

cooling was not sufficient for cooling surface of tube. This peltier

cooling system is usually used for small cooling system like water

purifier.

Robust tube is gained through this method and the

longitudinal elongation of Heat Shrinkable Tube is decreased.

Before applying TRIZ, the engineer only focused on changing

parameters of some components of this system. After applying TRIZ,

it is revealed that changing product is also possible way.

Figure15. Expansion pipe with peltier cooler

Figure16. Hardened Skin can prevent elongation

The longitudinal tolerance of conventional Heat Shrinkable Tube

was 10 mm. After using peltier cooler on the top of the expansion

pipe, and the tolerance reduced to 5mm per 100 mm of length. The

quality of Heat Shrinkable Tube was improved.

5. Conclusion

The case study shown in this paper is one of the examples which

are applied in real engineering problem in LS-Cable. Since TRIZ is

introduced in LS-Cable in 2001, TRIZ is promoted actively in LSCable.

In 2005, LS-Cable will focus on making infrastructure of TRIZ

to spread TRIZ more effectively, and will apply TRIZ to various

area. With co-work with research engineer and patent analysis team,

it is expected that synergy effect for improving R&D process will be

generated.

6. References

- Genrich Altshuller, 1997, 40 Principles, Technical Innovation

Center.

- Young-Ju Kang, Alexander Skuratovich, Pyeong-Kwan Chung,

2004, "TRIZ applied to Axiomatic Design, and case study;

improving tensile strength of polymer insulator", ETRIA 2004

Conference Proceedings, Nov 3-5.

- Genrich Altshuller, 1996, And Suddenly the Inventor Appeared:

TRIZ, the Theory of Inventive Problem Solving, Technical

Innovation Center.

|

ââåðõ

ââåðõ